ITML coordinates the implementation of learning systems distributed over computationally heterogeneous resources, leveraging Artificial Intelligence (AI) and Machine Learning (ML) methodologies for collecting and analysing in real-time a plethora of internal data (from the Original Equipment Manufacturer – OEM), external data (from suppliers and forwarding companies) and public data (from newsfeed), covering the complete logistics supply chain of the production site of a world-leading automotive manufacturer.

A “Smart Factory” is a complex ecosystem where data flow from machines and the plant floor to the Cloud, and subsequent information exchanges occur between all stakeholders in a supply chain. In an automotive smart factory, part demand calculation and ordering processes are carried out automatically, nevertheless, there are many causes for disruption in the supply chain leading to supply bottlenecks. Collection and joint assessment of dozens of different indicators for parts’ criticality (stock levels, transports, coverage, replenishment times, inhouse material movements, etc) and screening of external sources (newsfeed, weather forecast) to determine potential effects on the supply chain, can facilitate evaluation of the current supply situation and assessment of the effectiveness of all possible measures.

To cope with this expected richness of the model parameters, feedback and training data need to be requested continuously and by a multitude of sources, resulting in a -by default- global and hence, cross-border, AI model. Deep learning approaches can aggregate the underlying model inputs and gradually build the necessary user and context profiles, nonetheless the models need to continuously adapt to the influx of new data. Deep Learning (DL) is an ML paradigm that has gained outstanding interest for its ability to process large-scale, high-dimensional and complex data with several impacting applications to multimedia, natural language processing and more recently biomedical problems. DL, being an ML approach, requires considerable computational, communication and storage resources to produce effective results. DL models are typically run, in part or entirely, on Cloud resources. In contrast, Randomized Neural Networks, provide a state-of-the-art trade-off between efficiency and effectiveness in solving temporal learning tasks, allowing embedding learning functionalities even on low-power devices. The challenging missing element is the combination of these two approaches, so as to effectively navigate the essential tradeoff between accuracy and performance, making use of a wide range of available resources (Internet-of-Things (IoT) / edge / Cloud).

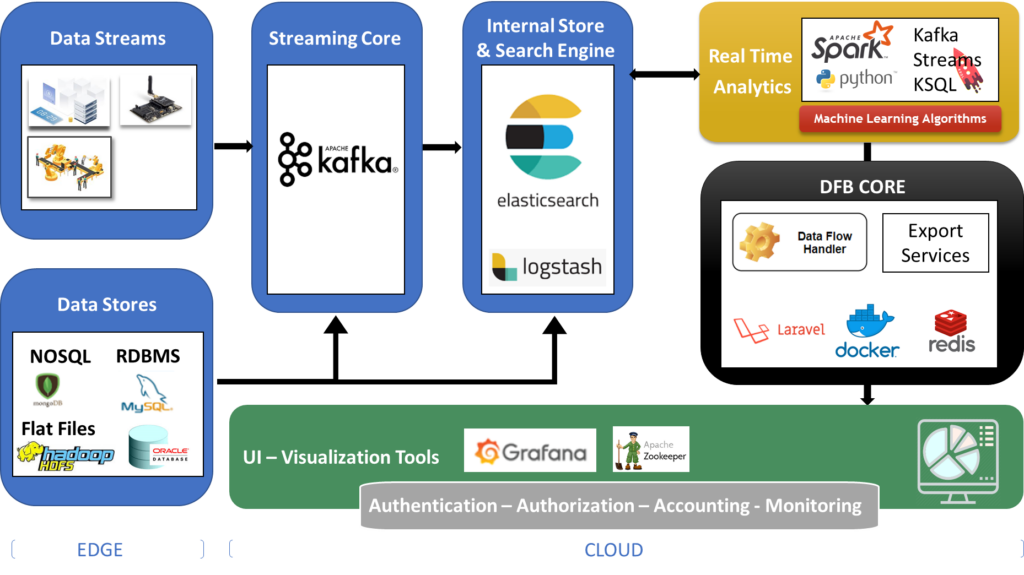

In AI4DI, ITML partners with a world-leading automotive manufacturer with the aim to provide an intelligent decision support system that effectively classifies the critical parts of the production line based on internal and external data sources, ultimately avoiding bottlenecks and reducing coordination and disruption risks within the entire supply chain. Towards this direction, ITML provides an ML-based decision support system that both supports centralised processing in the Cloud, as well as distributed intelligence embedded at the edge of the network. The Edge layer includes the devices and sensors that generate the data that feed the whole framework. These could be: (i) IoT devices; (ii) sensing devices; (iii) network data; (iv) historical data stored in databases or any other data that may be exploited by the data analytics and the decision support modules. The Cloud layer is the main data handling component of the architecture that provides the appropriate services to the users; (i) data analytics; (ii) predictive analytics; (iii) anomaly detection and decision support services. It also ensures the authenticity and integrity of data flows. A vast amount of collected data is being processed, refined and analysed here. Based on this analysis, decision-support services provide real-time detection of complex events and system’s malfunctions enabling real-time smart situation awareness and pro-active action. The system architecture is depicted in Figure 1.

Figure 1 – ML-Based Decision Support System Architecture.

The AI4DI project is coordinated by Infineon Technologies AG, it started in May 2019 and it will finish in April 2022 (3 years duration). The project will be implemented by a multidisciplinary consortium consisting of 41 partners from leading industrial organisations, top research institutes and innovation-driven SMEs. To find out more about the AI4DI project and its partners, follow us on Twitter.

AI4DI project has received funding from the ECSEL Joint Undertaking (JU) under grant agreement No 826060. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and Germany, Austria, Czech Republic, Italy, Latvia, Belgium, Lithuania, France, Greece, Finland, Norway.

The contents of this publication do not necessarily reflect the opinion of the European Union. The article reflects only the author’s view and the sole responsibility of this publication lies with the author. The Electronic Component Systems for European Leadership Joint Undertaking (JU) is not responsible for any use that may be made of the information contained therein.